What are incubators (setters) and hatchers

The two main pieces of equipment used in a hatchery are the incubator and hatcher. An incubator is also called a "setter" by many people. For hen eggs as an example, during the entire incubation period, hen eggs need around 21 days to hatch. The 21 days are split into two parts, from day 1 to day 18 eggs will be in the incubator, and on the 18th or 19th day, eggs will be transferred to the hatcher, and stay inside the hatcher for 2-5 days until most of the chicks hatch.

So the whole incubation process for hen eggs is : 18 days inside incubator (setter) +3-5 days inside hatcher= 21-23 days for chicks to hatch from eggs.

What are the differences between the incubator (setter) and hatcher?

During the early incubation process, the eggs need to be rotated frequently to prevent the embryos from sticking to the surrounding membranes. Therefore, modern incubators generally design the egg tray as a structure with holes, and eggs are placed in each hole, so that the rotation of the eggs can be easily done in the egg tray without falling out. This structure also allows the circulation of air around the eggs, for the eggs to obtain enough oxygen, extract carbon dioxide they produce as they grow and allow the circulation of air to transfer heat to or from the eggs.

When the chicks are ready to hatch from the shell, there is no need to rotate the eggs, and the eggs need to be transferred to a basket to prevent the chicks from falling out of the hole in the egg tray of the incubator when hatching.

When chicks start pipping out, the chicks start to use their lungs to breathe, and produce much more heat than during incubation. When chicks come out from their egg shells, the water inside the eggs will also come out, and influence the humidity level inside the hatcher. The setting temperature and humidity are usually different between an incubator and hatcher. For example, the temperature of eggs in the incubator is usually about 37.5 to 38°C, and the temperature of eggs in the hatcher is about 37°C.

When chicks hatch, the hairy chicks' tiny feathers will produce a lot of fluff inside the machines. So during the hatching period, it will be much dirtier than during incubation period.

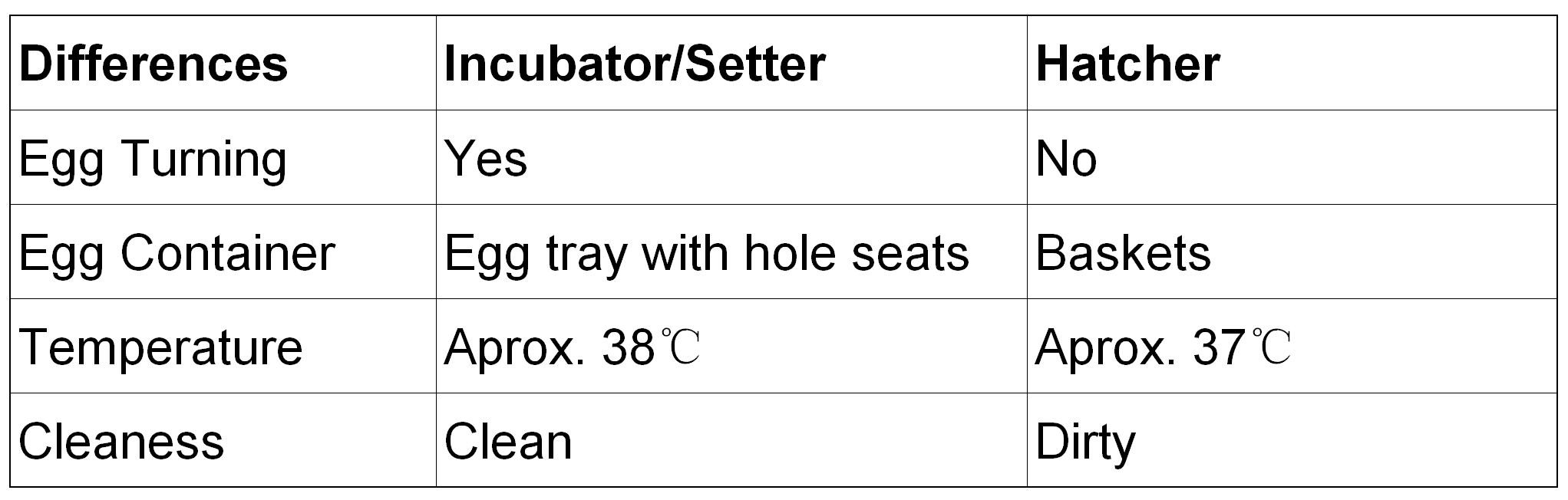

The differences compared in a table:

Can a machine work as both incubator and hatcher?

If the two functions are not used at same time, then the incubator can be used as a hatcher too.

A machine with two functions should have proper capacity. Inside a hatcher, chicks produce a lot of heat. and if there are too many chicks inside one machine, it will be hard to control the proper temperature inside. Most incubator suppliers only make hatchers with a capacity of 10,000~20,000 eggs, and some make up to about 40,000 eggs. So a machine that has both functions, will have the egg capacity limited by the hatcher capacity.

As temperature/humidity setting for incubator and hatcher are different, after eggs have moved from the incubator to hatcher, the settings are modified.

Both incubator trolleys with egg trays and hatcher trolleys with hatching baskets will supplied with the machine when buying. The incubator's egg turning function will also come with the machine.

When a farmer is buying eggs from other places, hatching chicks once every 21 days or more, then he can use the incubator like this. For example, if he only has one or two broiler farms, he may need one batch of chicks every month or more. Or if he has several layer farms, and every one month or more he needs one batch of chicks. With one machine working for both functions at different time, the farmer can save costs when buying the machine, as he only needs one cabinet with two kinds of trolleys with trays or baskets.

If a farmer has his own breeding parent stock, then he will get eggs every day from the farm. And eggs usually are not stored for more than one week before incubation, otherwise the hatching result will be reduced. The farmer will hatch at least once a week or twice a week, then his incubator capacity will be 3 times or 6 times of his hatcher capacity. In this case, the farmer needs to have both incubators and hatchers, separately.

Combo Incubator/ Combined Incubator

For small incubators with a capacity of no more than 1500 eggs, some incubators have the combined functions of an incubator and hatcher - combo units. One machine, rather than two, can save the costs of manufacturing a separate machine. This kind of incubator is also called a combined incubator, or combo incubator. However, for large incubators with egg capacity exceeding 10,000, the incubators will seldom use the combined design, because of its drawbacks:

When chicks hatch, the chicks fluff produced will make the inside of the machine very dirty, and difficult to clean. Fluff will bring organic dirt into into the machine, take bacteria from the chicks and possibly contaminate the early age eggs nearby in the same incubator.

Secondly, as embryos incubating at different times require different temperatures and humidity. When filling eggs and chicks in an incubator, only one temperature and humidity can be used, and the embryo cannot obtain the best environment and thus cannot ensure the best hatching settings - so a compromised or averaged temperature and humidity level needs to be managed for a combo unit incubator.